BagUp's Commercial size trash bags Recommended by Whom You Know

Some projects in life require a bigger garbage bag. With BagUp's Commercial size trash bags you don't need to use up lots of small trash bags to get the job done! These bags also have a cardboard dispenser which makes it really easy to grab another bag when you need one! You can keep the box underneath your sink too because it doesn't take up a lot of space to store! BagUps are made in the USA and are committed to a zero waste footprint! They use biodegradable bags and 100% recyclable cardboard so that you can feel good about using this product!

Having a supersized bender? Working on a remodeling project? These BagUps are not just for commercial businesses. With this amazing patented system of interlocking, it takes the mess and stress out of cleaning up and cleaning up some more. Plus, with its biodegradable system you cannot go wrong. So support a product Made in the USA which also employs Veterans and people with disabilities.

As much as I enjoy the tall kitchen size "BagUps", my husband enjoys the commercial size even more. A quick and convenient trash bag dispensing system, "BagUps" is a great addition to any household. Biodegradable bags which come in a 100% recyclable cardboard box, this company is committed to a zero waste footprint! Add the fact that they are made in the USA and packed and assembled by Veterans and people with disabilities and what is not to like? By using "BagUps", you are contributing to a healthier environment (BagUps biodegrade in two years as opposed to 2,000 years for conventional trash bags), supporting an American made product and employing Veterans and people with disabilities. Purchase "BagUps" and feel good about your garbage and good about yourself!

The one thing I can't stand is trying to find trash bags that fit my outdoor trash can. The BagUps commercial size bags fit perfectly. During the spring and summer I am always out in the yard doing some kind of work and these bags held up perfectly. Plus, it was nice that I could keep working and have the bags replace themselves. I have a huge tree in my front yard and it dumps lots of leaves in the fall. The commercial size BagUps will be perfect. I won't lose time having to change bags and "force" them to stay on. I will never use another bag for yard work. I highly recommend them!

***

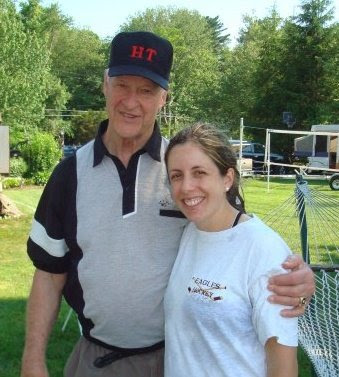

BagUps: Creating Employment Opportunity for Disabled Vets

In 1990, Jack Licata's fiancee was in a car accident that left her with a head injury and disabled.

In the 10 years during her rehabilitation, he spent thousands of hours at her side in hospitals assisting her with cognitive and physical therapy. He also got to know many of the other patients. "These were people just like you and me who, through no fault of their own, were disabled," said Licata. "There were people who got hurt in the service, were in a car accident, or had a stroke. I decided that, if there ever was a way I could make a difference for that community, I would."

Now, with the company ReCircle Brands, Licata is achieving his goal. He has developed the company's first patented product, BagUps, and is focusing on growing his business.

Licata's inspiration for the product came while he was working as a nuclear missile launch officer in the Air Force. Once a month he had "office duty," and this included emptying the garbage can at the end of the day. "I hated it!" he said. Convinced that there was a better way, he did some research at fast food restaurants and then came up with the concept for BagUps.

"The product answers the question, 'where is the next garbage bag?' after I empty the garbage," he said. "Usually it's somewhere like under the sink or in a cabinet in the very back storage room. BagUps puts bags where they belong, right there in the bottom of the can."

BagUps saves lots of time: it takes three seconds to change a bag using BagUps, as opposed to a minute and a half using other trash bags. This can mean significant savings for large institutions using this product. According to a study done by a hospital that used BagUps, the product saves one man-hour per employee per day. "This can amount to hundreds of thousands of dollars per year," said Licata.

Another advantage of the product is that the bags and cardboard are biodegradable. In addition, it is made entirely in the United States, and currently exclusively in New Jersey. Lastly, in keeping with Licata's goal to help the disabled community, the assembly of BagUps lends itself to work that can be completed by residents of the Veterans Administration and other occupational centers. "The work gives disabled workers an opportunity for a life and some self-worth," said Licata.

Licata is still working on locating some of these communities in New Jersey; he will soon be employing Veterans from the Wounded Warrior program here. His business model includes plans to go national in concert with the VA hospital, which would add significantly to his current customer base of seven VA Hospitals throughout New Jersey, New York, Long Island and the upstate Hudson Valley. The product would be produced in occupational centers located near the VA hospitals. "Our business strategy is to have the product 100 percent made in America by veterans and people with disabilities, even though we could make more money by outsourcing the production overseas."

For every 1,000 BagUps that the company produces, they create a job for one person a week. At this early startup stage of the business, the assembly of the bags would run for a few weeks at a time, providing employment for 10-15 people.

BagUps has been shown on QVC and the Shopping Channel. The product has also been shown as one of the top five green products of the year on MSNBC. The product is being distributed through US Foods, one of the largest distributors in the U.S. "Currently we're in a few boutique stores, but only need one good contract with a large distributor or government agency such as the the VA, then we'll be able to ramp up within a few days and provide a few hundred jobs," said Licata.

Licata believes that by focusing on hiring veterans, his company could also put a dent in the number of homeless veterans. The VA estimates that 107,000 veterans are homeless on any given night and that, over the course of a year, approximately twice that many experience homelessness. "If the VA bought my system, the government would save on the efficiencies of the product, while at the same time I could employ a huge percentage of homeless veterans to assemble the product for them," he said.

Licata is looking to expand his product line by developing additional biodegradable products "not built to last." He envisions a line of biodegradable tablecloths, drop cloths, and other products, which would all create U.S.-based jobs for the disabled and homeless veterans.

"My company can make a huge difference for veterans and disabled people right in our backyard; we think it's a win-win-win: people will like it as soon as they try it," he said.